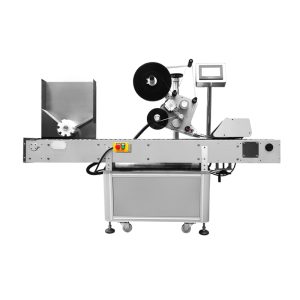

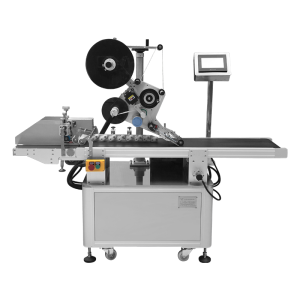

Automatic Round Bottle/Flat Bottle Labeling Machine

Applicazione

Automatic round bottle/flat bottle labeling machine is used for irregular and regular shaped products to attach double-side labels at the same time or single side labeling based on needed. Widely used in chemicals, petrolio, Olio motore, dish soap, shampoo, Gel doccia, beverage cans…eccetera.

Automatic Round Bottle/Flat Bottle Labeling Machine

Caratteristiche

1.SS304 machine body, aluminum alloy,engineering plastics (chain plate), etc.,complies with GMP usage requirements.

2.Computer control,PLC cooperates with large human-machine interface control, has automatic learning of label length, can adapt to different labels, and is easy to operate and adjust.

3.Multiple sets of labeling parameter memory can quickly change different products for labeling.

4.Conveyor and pressing mechanism both use same power source,high-quality AC motors drive.

5.Bottle dividing mechanism and correction mechanism are driven by stepless speed regulating motors,speed adjust independently,stable labeling.

6.Label scraping mechanism uses a sponge spring steel plate combined brush,label pressing mechanism uses a combined sponge roller no bubbles generate during labeling.

Parametri tecnici

| Nome | Automatic Round Bottle/Flat Bottle Labeling Machine |

| Velocità di etichettatura | 0~ 25 metri/min, regolabile |

| Precisione dell'etichettatura | ± 1 mm (esclusi gli errori di prodotto ed etichetta) |

| Rotolo di carta applicabile Dia. | He.76mm, max dia.300mm |

| Dimensione della bottiglia applicabile | Smallest: 30mm(W)X 50mm(H),Max.:120mm(w)X 400MM(H) |

| Dimensione dell'etichetta applicabile | Height: 10mm – 200mm Width: 16mm – 400mm |

| Max height of label | 200mm |

| Dimensione |

3000X1450x1400mm |

| Peso della macchina | 400kg |

| Voltaggio | 220V 50/60Hz |

Video della macchina

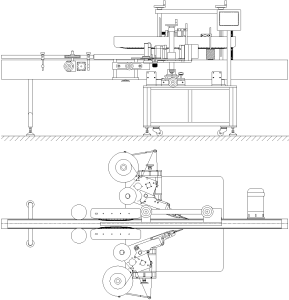

Mechanical structure

Machine Structure Diagram

SUNBIOPACK

SUNBIOPACK