454Machine de conditionnement de cire de paraffine G

Application

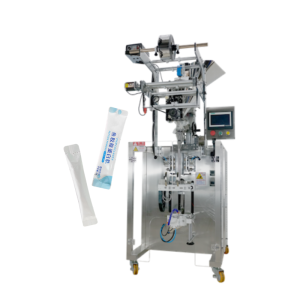

La machine convient à l'industrie alimentaire / médicament / chimique / cosmétique, mesure automatique&packing liquids/sauce such as paraffin wax/chili sauce/tomato paste/honey/cream, etc..

With exhaust rod through bag sealing, so there won’t be air inside after packaging, the package is more beautiful and saves space without air inside.

Paraffin Wax

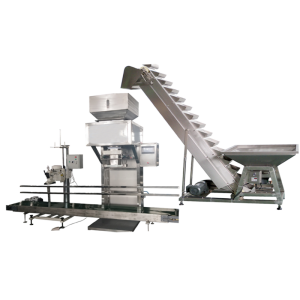

Machine de conditionnement de cire de paraffine

Caractéristiques

1.Automatic complete process of film pulling/bag forming/measuring/filling/bag sealing/cutting and counting function,il peut également faire correspondre l'imprimante de date(Impression du numéro de lot) et dispositif d'alimentation automatique basé sur la demande des clients.

2.PLC Contrôle, Fonctionnement du panneau d'écran tactile,exécuter stable / ajustement facile / détection précise. Contrôleur de température indigent et contrôle du PID pour assurer le plage d'erreur de température contrôlée à l'intérieur 1 degré centigrade.

3. Machine frame SS201 and material contact part is SS304.

4.Convient pour le film en plastique et le film en papier, comme BOPP / polyéthylène,aluminium/Polyethylene, Papier / polyéthylène,Polyester / aluminizer / polyéthylène, Nylon / pp et ainsi de suite.

5. All the Electronic components adopt international famous brand excluding motor(the motor use regular domestic brand).

Paramètres techniques

Model: SP-420

Plage de mesures:200-1000ml

Taille du sac: L:80-300mm w:50-200MM.

Vitesse d'emballage:5-15 sacs / min basé sur le matériel d'emballage&poids d'emballage

Dimension:1460* 2160* 3230 MM(L * w * H)

Poids de la machine: 600kg

Tension:AC380V /50-60Hz

Pouvoir:6Kw

Type de sac

Back Sealed Bag

Vidéo des machines

The paraffin wax packing machine need to work with air compressor and heating mixing tank for paraffin wax material.

Heating Mixing Tank

Description of Heating Mixing Tank

The stainless steel mixing tank is constructed of SS304 and features heating and stirring functions. It consists of a top-opening tank, lid, agitator, and a sealing system. The tank and lid are flange-sealed or welded, and interior surface is mirror-polished. The agitator drive includes a motor and a reducer, with a typical speed range of 50 to 1500 rpm. The heating system supports jacket electric heating, coil heating, and thermal oil circulation, with a temperature control accuracy of ±1°C and a temperature sensor.

Parameters of Heating Mixing Tank

- Volume: 500L, optional 1000L/1500L.

- Material: stainless steel 304;

- Double layer tank, with the heating motor 30Kw, stirring motor 1.5KW, 220V-240V, 60HZ, 3P

- Including the electric control box;

- Two outlets/tank.

- 500L tank dimension: 120*170cm

- Poids: 200kg

Silent Oil Free Air Compressor

Air compressor, support 1set SP-420 packing machine, and power 3.5KW, and power 7.5KW to support 2 sets packing machine,

Working Principle of Air Compressor

As the motor runs, air flows through air filter into the compressor, compressing the air. The compressed gas enters air tank, causing the pressure gauge to rise to 8 bar. When the pressure exceeds 8 bar, the pressure switch senses the pressure and automatically closes, shutting down the motor. The gas is then exhausted through the ball valve, driving connected equipment. When pressure in air tank drops to 5 bar, the pressure switch automatically opens, and the compressor resumes operation.

SUNBIOPACK

SUNBIOPACK