454Máquina envasadora de cera de parafina G

Solicitud

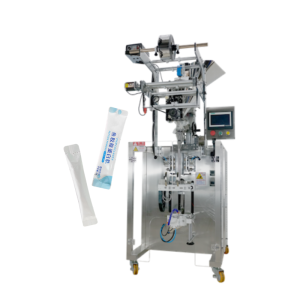

La máquina es adecuada para la industria alimentaria/medicina/química/cosmética., medición automática&packing liquids/sauce such as paraffin wax/chili sauce/tomato paste/honey/cream, etc..

With exhaust rod through bag sealing, so there won’t be air inside after packaging, the package is more beautiful and saves space without air inside.

Paraffin Wax

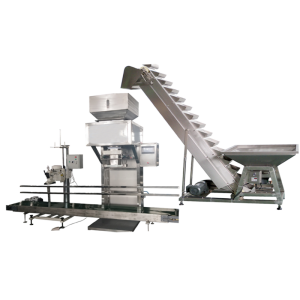

Máquina envasadora de cera de parafina

Características

1.Automatic complete process of film pulling/bag forming/measuring/filling/bag sealing/cutting and counting function,También puede combinarse con la impresora de fecha.(número de lote de impresión) Y dispositivo de alimentación automático según la demanda del cliente..

2.control PLC, funcionamiento del panel de pantalla táctil,funcionamiento estable/fácil ajuste/detección precisa. Controlador de temperatura inteligente y control PID para garantizar la rango de error de temperatura controlada dentro 1 grados centígrados.

3. Machine frame SS201 and material contact part is SS304.

4.Adecuado para rollos de película de plástico y rollos de película de papel., como BOPP/Polietileno,aluminium/Polyethylene, Papel/Polietileno,Poliéster/Aluminizador/Polietileno, Nailon/PP, etc..

5. All the Electronic components adopt international famous brand excluding motor(the motor use regular domestic brand).

Parámetros técnicos

Modelo: SP-420

Rango de medición:200-1000ml

Tamaño de la bolsa: L:80-300mm W:50-200milímetro.

Velocidad de embalaje:5-15 bolsas / min basado en el material de embalaje&peso del embalaje

Dimensión:1460* 2160* 3230 milímetro(largo x ancho * H)

Peso de la máquina: 600kg

Voltaje:AC380V /50-60Hz

Fuerza:6kilovatios

Tipo de bolsa

Back Sealed Bag

vídeo de la máquina

The paraffin wax packing machine need to work with air compressor and heating mixing tank for paraffin wax material.

Heating Mixing Tank

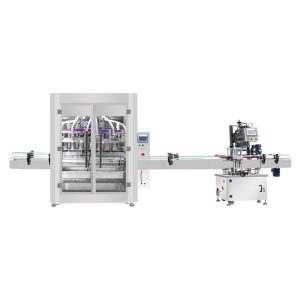

Description of Heating Mixing Tank

The stainless steel mixing tank is constructed of SS304 and features heating and stirring functions. It consists of a top-opening tank, lid, agitator, and a sealing system. The tank and lid are flange-sealed or welded, and interior surface is mirror-polished. The agitator drive includes a motor and a reducer, with a typical speed range of 50 to 1500 rpm. The heating system supports jacket electric heating, coil heating, and thermal oil circulation, with a temperature control accuracy of ±1°C and a temperature sensor.

Parameters of Heating Mixing Tank

- Volume: 500L, optional 1000L/1500L.

- Material: stainless steel 304;

- Double layer tank, with the heating motor 30kilovatios, stirring motor 1.5KW, 220V-240V, 60Hz, 3P

- Including the electric control box;

- Two outlets/tank.

- 500L tank dimension: 120*170cm

- Peso: 200kg

Silent Oil Free Air Compressor

Air compressor, support 1set SP-420 packing machine, and power 3.5KW, and power 7.5KW to support 2 sets packing machine,

Working Principle of Air Compressor

As the motor runs, air flows through air filter into the compressor, compressing the air. The compressed gas enters air tank, causing the pressure gauge to rise to 8 bar. When the pressure exceeds 8 bar, the pressure switch senses the pressure and automatically closes, shutting down the motor. The gas is then exhausted through the ball valve, driving connected equipment. When pressure in air tank drops to 5 bar, the pressure switch automatically opens, and the compressor resumes operation.

SUNBIOPACK

SUNBIOPACK